Pipe Brazing

COURSE LENGTH: 15 DAYS (120 HOURS)

COURSE LOCATIONS: Norfolk VA

The purpose of this course is to train students on Naval Sea Systems Command (NAVSEA) technical manual 0900-LP-001-7000, Fabrication and Inspections of Brazed Piping Systems. Students will be taught the standards for materials, workmanship, qualifications, inspection, and quality control measures for the fabrication of brazed piping systems. Students will obtain a Navsea Brazing Qualification upon receiving a satisfactory Non-destructive test on a vertical test piece and a horizontal test piece.

COURSE OBJECTIVES

Purpose –

The purpose of this course is to train students on Naval Sea Systems Command (NAVSEA) technical manual 0900-LP-001-7000, Fabrication and Inspections of Brazed Piping Systems. Students will be taught the standards for materials, workmanship, qualifications, inspection, and quality control measures for the fabrication of brazed piping systems. Students will obtain a Navsea Brazing Qualification upon receiving a satisfactory Non-destructive test on a vertical test piece and a horizontal test piece.

Reference –

- Naval Sea Systems Command (NAVSEA) technical manual 0900-LP-001-7000,Fabrication and Inspections of Brazed Piping Systems

- OSHA Standards ,General Industry, (29 CFR 1910 )

- OSHA Standards, Maritime ( 29 CFR 1915, 1917, 1918 )

Functions –

Workmanship, inspection, and materials will be taught in a class room setting( the company sending the student has to provide an approved procedure, process, position ,base material types, and pipe wall thickness). Students will take the knowledge to the mock up area and fabricate / braze test pieces on work tables to learn the fundamentals of the brazing process. The student will fabricate and braze in a test booth for the Navsea test qualification.

INTRODUCTION

Covers definitions, pipe classifications and qualification requirements.

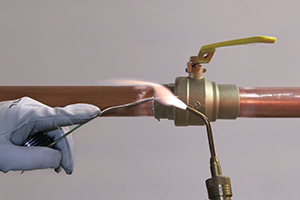

FABRICATION METHODS

Trains personnel the correct fit up requirements, brazing a joint and qualification requirements.

TOOLS

Covers the tools for brazing and how to use a oxygen and acetylene torch safetly.

Working Conditions

This position is considered SHOP/OUTDOORS which is characterized as follows.

- Primarily outdoors during the day

- Frequently working on or near moving equipment and vibrating equipment

- Humidity is frequently above 90%

- Noise is over 85 decibels

- Light is intense/glare ( Student should have safety glasses with a number 3 or 4 shaded lens )

- Occasional exposure to open fire/flames/sparks

- Frequent exposure to airborne dust, fumes, and gases

- Work surface is stable

- Requires working in very hot (above 90 F degrees) or very cold (below 32 F degrees) temperatures

- Prolonged standing, squatting, bending and reaching.

- Continual exposure to hot metal suffices with potential burn injuries.