Maritime Insulator Basics – 5 Days

COURSE LENGTH: 5 DAYS (40 HOURS)

COURSE LOCATIONS: Norfolk VA, National City CA, Bremerton WA

The purpose of this training is to provide the student with a basic understanding and skill to identify, measure, cut and repair anti-sweat and thermal insulation.

COURSE OBJECTIVES

PURPOSE

- Describe the purpose of Maritime insulation

Identify the materials used in Maritime Insulation - Identify the tools of the trade and their proper usage

- Demonstrate the use of measurement tools and basic math calculations in Maritime Insulation

- Recognize the PPE used in Maritime insulation

- Demonstrate the removal procedures used in Maritime Insulation

- Demonstrate the ability to Measure, Cut, Fit and Install Tube Rubber on a length of pipe

- Demonstrate the ability to install fibrous cloth (Lagging) to installed Tube Rubber

REFERENCES

- Naval Ship Technical Manual, Chapter 635

- MIL-STD-769

FUNCTIONS

Trainees will conduct hands on application within various shipboard mockups and tabletop units.

A. Remove Tube rubber insulation and re-install tube rubber on straight pipe. Apply lagging cloth over insulation and complete by using the fosters 3036 paste.

B. Fabricate oversize insulation on flanges and Hangers.

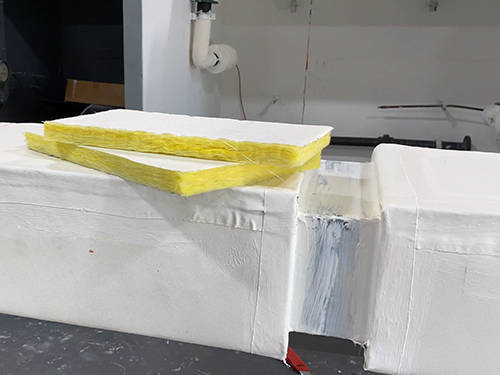

C. Remove fiberglass duct insulation, measure cut and install new fiberglass insulation. Seal all seams with lagging seam tape and paste.

D. Replace a section of bulkhead fiberglass insulation. Install new studs and stud caps as needed. Apply insulation tape to seal joints and edges.

INSULATION MATERIALS

Explains the purpose and requirements for insulation, materials used and the safety requirements when handling (Safety Data Sheets).

TOOLS

Trains personnel in the proper use of tools used for insulation.

PERSONAL PROTECTIVE EQUIPMENT (PPE)

Trains personnel on hazard recognition when working with insulation and how to mitigate them.

INSULATION REMOVAL

Explains the proper procedures when removing insulation.

INSTALLING BOARDGLASS

Explains the process of installing boardglass on ducting, beams and bulkheads.

INSTALLING TUBE RUBBER

Explains the process of installing tube rubber on pipe.

Introduction – Purpose of insulation on Naval Vessels.

Insulation Materials used on Naval Vessels – Show the different types of insulation used.

Tools of the trade – Show the tools used in the trade and proper usage.

PPE – Show all the different PPE used in the trade and the proper usage.

Vent Duct Insulation – Show the methods of removal and installation.

Tube Rubber Insulation – Show the methods of removal and installation. Demonstrate how to measure, cut and install tube rubber.

Sheet Rubber Insulation – Show the uses for sheet rubber and demonstrate how to use for oversizes on Flanges.

Bulkhead Insulation – Show the proper removal and installation methods.

Insulation Adhesives and Cements – Show the different types and uses.

Working Conditions

This position is considered Mock up/Classroom which is characterized as follows.

- Between Class room and Mock up during the day

- Frequently working with sharp tools while standing on ladders and in awkward positions

- Humidity is frequently above 90%

- Frequent exposure to airborne dust, fumes, and gases

- Requires working in very hot (above 90 F degrees) or very cold (below 32 F degrees) temperatures