Cableway Inspection & Repair – 5Day

COURSE LENGTH: 5 DAYS (40 HOURS)

COURSE LOCATIONS: Norfolk VA

The purpose of this course is to train inspectors on Naval Sea Systems Command (NAVSEA) technical policy, and requirements.

Plus take any actions necessary for the performance of periodic comprehensive shipboard cableway inspection assessments conducted per the Cableway Assessment Program established in the Joint Fleet Maintenance Manual (JFMM) and in accordance with NAVSEA INSTRUCTION 9304.1E

COURSE OBJECTIVES

REFERENCES

- COMUSFLTFORCOMINST 4790.3C, Joint Fleet Maintenance Manual, 19 September 2017

- MIL-STD-2003, -1, -2, -3, -4, -5, Electrical Plant Installation Standard Methods for Surface Ships and Submarines, 3 September 2009

- MIL-HDBK-299, Cable Comparison Handbook, Data Pertaining to Electric Shipboard Cable, 15 October 1991

- S9086-KC-STM-010/300, NSTM Chapter 300, Electric Plant – General, 1 February 2012

- NAVSEA INSTRUCTION 9304.1E

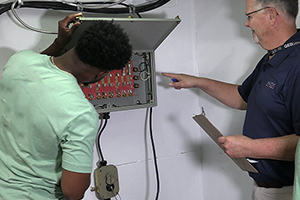

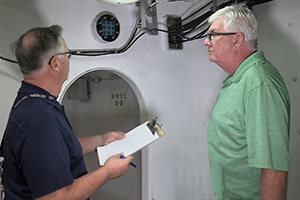

FUNCTIONS – Trainees will conduct hands on application on various shipboard mockups. Trainees will perform a cable way inspection in a mock up utilizing the knowledge gained from videos and power points to identify deficiencies and to classify each deficiency according to NAVSEA INSTRUCTION 9304.1E.

INTRODUCTION

Train personnel on the NAVSEA technical policy and actions necessary to identify and correct electrical cable and cableway hazards.

REMOVAL AND INSTALLATION

Covers the requirements when removing and installing cable and cableways on Navy ships.

STUFFING TUBES

Covers the requirements when installing stuffing tubes.

MULTICABLE PENETRATIONS

Covers the requirements when installing mulicable transits and plugs.

CHAFING RINGS

Covers the installation of chafing rings.

HANGERS

Covers the requirements of installing hangers.

Penetration of Equipment and Connection Boxes – Identify Pentetrations to Equipment and Connection Boxes

Multi-Cable Penetration – Identify different types of Muli-Cable Penetrators

Hangers – Identify different types of hangers and hanger spacing.

Banding – Identify different types of bands, and retention devices.

Lesson Topics – Responsibility of Employer

Chaffing Rings – Identify different types of Chaffing rings.

Dead-Ended Cables – Identify improperly and properly dead-ended cables.

Spliced Cables – Identify different types of spliced cables

Cable Jacket Repairs – Identify different types of cable jacket repairs.

Removal and Installation Technigues – Identify proper installation and removal techniques.

Cableway Inspection – Identify different catagories of cableway discrepancies.

Testing Cables – Identify proper requirements for testing cables

Special Tools and Equipment – Identify different types of hangers, hanger spacing and installation.

Wiring Techniques – Identify different types of wiring techniques..

Basic Cable Terminations – Identify basic cable terminations

Planning Cable Routes – Identify proper planning of cable routes

Performance Review Evaluate for Remediation

Instructor Responsibilities – This position has no supervisory responsibilities

Reporting Relationship – Will report to assigned supervisor

Qualifications – None

Working Conditions

- Classes will be taught using Power Points and Videos.

- Classroom environment Building 9A

- Mock-ups used for hands on inspection, Building 9B