Blueprint Reading Qualification

COURSE LENGTH: 3 DAYS (24 HOURS)

COURSE LOCATIONS: Norfolk VA

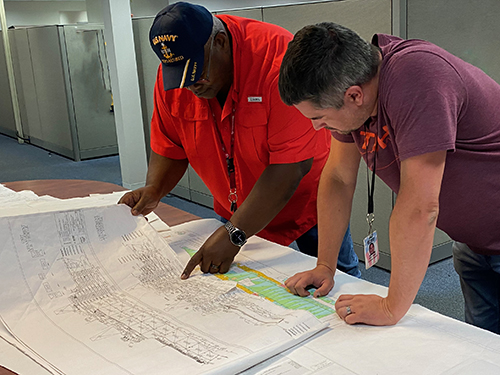

The purpose of this course is to train students on the components which compose a NAVSEA drawings. Students will be taught the standards of mechanical, electrical, and structural drawings.

Students will learn in the classroom and use shipboard mock-ups for practical exercises.

COURSE OBJECTIVES

REFERENCE

- NAVEDTRA 14057

- NAVEDTRA 14040

- OSHA Standards, Maritime ( 29 CFR 1915, 1917, 1918 )

FUNCTIONS

NAVSEA drawings for mechanical, electrical, and structural ship repairs are used to teach the knowledge required for an individual to comprehend the basic understanding of ship requirements to accomplish a ship repair. Students are taught the different components, line characteristics, views, and the different type of drawings. Students are given a guide and examples to follow along with instructor at their desk. Drawings representing QED shipboard mockups are given to the student during the class for practical exercises.

BASICS

Provides personnel the fundamental information, understanding, and concepts necessary to use technical drawings and blueprints when performing research or inspections.

ELECTRICAL

Trains personnel the component symbols, dimensions, general notes, descriptions and pictorial views associated with electrical.

PIPE

Trains personnel the component symbols, dimensions, general notes, desriptions and pictorial views associated with piping.

STRUCTUAL

Trains personnel the component symbols, dimensions, general notes, descriptions and pictorial views associated with structural.

General Information Blocks – Explain and show where and what each type of information block represents

Line characteristics – Define and show each type of line

Projections and Views – Define and show examples of projections and views

Types of Drawings – Explain and demonstrate the different drawing types

Mechanical drawing – Explain how a mechanical drawing is interpreted

Material types of a mechanical system – Show the material types in the classroom by using examples obtained from the ship.

Mechanical symbols – Teach and demonstrate symbols representing the different fittings in a system diagram

Visualizing views – Teach the assembly a mechanical system by placing pipe fittings and pipe in the correct orientation IAW a drawing

Electrical Drawings – Explain how a electrical drawing is interpreted

Types of electrical drawings – Show and explain the different type of electrical drawings

Cable tags – Explain the formats on reading electrical cable tags

Electrical symbols – Explain and show the electrical smybols and how they are used in drawings

Structural drawings – Explain how a structural drawing is interpreted

Weld joint types – Show and explain the different weld joint types

Weld joint symbols – Explain how to read a weld joint symbol on a drawing

Ship compartmentation – Explain the compartmentation labeling method

Instructor Responsibilities – This position has no supervisory responsibilities

Reporting Relationship – Will report to assigned supervisor

Qualifications – None

Working Conditions

This position is considered SHOP/OUTDOORS which is characterized as follows.

- Primarily outdoors during the day

- Frequently working on or near moving equipment and vibrating equipment

- Humidity is frequently above 90%

- Noise is over 85 decibels

- Light is intense/glare

- Occasional exposure to open fire/flames/sparks

- Frequent exposure to airborne dust, fumes, and gases

- Work surface is stable

- Requires working in very hot (above 90 F degrees) or very cold (below 32 F degrees) temperatures